Tungsten Carbide EDM Blocks

Why Us?

• All grades are proven in their application.

• Products stocked globally for quick delivery. • Standard and corrosion-resistant

grades.

• 200 standard sizes with custom sizes

available upon request.

• Application, metallurgical, and process

optimization services.

Expertise in Cemented Tungsten Carbide Metallurgy

Our globally renowned portfolio of grades for metalforming and stamping is based on

30 years of research and development of tungsten carbide based materials.

Withstand Extensive EDM

Our latest grades were developed with

a proprietary binder system and maintain the hardness and mechanical properties of

our conventional grades. They resist the corrosion, pitting, and cracking commonly

experienced during electrical discharge machining, especially in thick punches and

large die segments.

EDM Blocks

The Goode Carbide proprietary manufacturing processes result in superior, consistent

mechanical properties throughout the product lifecycle.

|

Grade |

Nominal Binder(%) |

Grain Family |

Hardness |

Average TRS |

||

|

HRA |

HV30 |

PSI |

Mpa |

|||

|

GD855 |

10 |

submicron |

91.8 |

1580 |

420500 |

2900 |

|

GD466 |

12 |

fine |

90.0 |

1360 |

480000 |

3310 |

|

GD887 |

15 |

submicron |

90.2 |

1380 |

435000 |

3000 |

|

GD650 |

15 |

submicron |

90.2 |

1380 |

550000 |

3790 |

|

GD750 |

15.5 |

submicron |

90.7 |

1440 |

625000 |

4310 |

Note: Made-to-order blocks and preforms are available in a variety of grades for specialty applications

EDM Blocks

Unlike other carbide manufacturers, we produce our powders from the raw materials, this guarantees the highest quality tungsten carbide throughout the process and maximizes performance for the end user

|

Grade |

Grade |

|

GD855 |

Composition: 10% corrosion-resistant binder with submicron grain structure. Very good wear resistance with high edge sharpness but less shock resistance than higher binder grades. Excellent for EDM operations and good in non-ferrous applications. Application: ISO K-30 grade with ideal wear resistance in high-speed stamping, medium, thin sheets — coining brass (.010" thick), can die ironing rings, non-gummy steels, compacting dies, stamping dies for razor blades, lead frames (thin copper .030"), annealed copper, and draw dies (300 series stainless steel). |

|

GD466 |

Composition: 12% corrosion-resistant binder with medium/fine-grain structure. Very high strength for heavy impact with low wear properties. Application: For standard stamping — impacting punches, coining dies, forming dies, can die punches, swaging dies, cold forming, very severe draw dies for .075" thick cold-rolled steel, piercing punches (305 stainless steel), and gummy steel. |

|

GD887 |

Composition: 15% corrosion-resistant binder with submicron grain structure for lead frame and connector stamping. Very high strength and excellent wear resistance for medium-impact applications. Application: Stamping dies for razor blades, electronic stamping, lead frame dies, laminations, spring steel stampings, and coining dies (hard metal). Not recommended for stamping thick stainless steel. Use in place of CD650 for difficult to EDM parts, or if corrosive die lubricants are used. |

|

GD650 |

Composition: Conventional 15% cobalt binder with submicron grain structure for lead frame and connector stamping. Very high strength and excellent wear resistance for medium-impact applications. Our most popluar grade for general purpose stamping. Application: Stamping dies for razor blades, electronic stamping, lead frame dies, laminations, spring steel stampings, and coining dies (hard metal). Not recommended for stamping thick stainless steel. |

|

GD750 |

Composition: Conventional 15.5% cobalt binder with ultra-fine submicron grain structure for lead frame and connector stamping. Very high strength and excellent wear resistance for low-impact applications. Application: Extremely thin punches or tools with very fine features will benefit from the ultra-fine submicron grain structure, which helps to prevent premature corner washout and maintain edge strength. Also may be used as an upgrade to CD650, due to increased hardness. |

Ready to Meet your specific needs We have a large selection of conventional and low-corrosion rectangular blanks in stock. Each is sinter-HIP processed and stress-relieved for optimum performance in EDM machining. Blocks are available in standard sizes, which are individually packaged for easy delivery and handling.

Standard Blocks:

• Nominal dimensions are shown in the chart below.

• All blanks are provided with grinding allowance as shown in the tolerance chart.

• Each block is sinter HIP and stress relieved for EDM machining.

|

Length |

Width |

Thickness |

|

200 |

200 |

15-45 |

|

150 |

150 |

15-45 |

|

150 |

100 |

15-45 |

|

150 |

130 |

15-45 |

|

150 |

80 |

15-45 |

|

120 |

120 |

15-45 |

|

100 |

100 |

15-50 |

|

100 |

50 |

15-50 |

|

100 |

45 |

15-50 |

|

80 |

55 |

10-50 |

|

80 |

40 |

10-50 |

|

70 |

35 |

5-50 |

|

45 |

25 |

3-20 |

|

35 |

19 |

5-30 |

|

20 |

20 |

5-20 |

|

18 |

13 |

5-20 |

Surely that we can offer any sizes upon the clients’ customized requirement

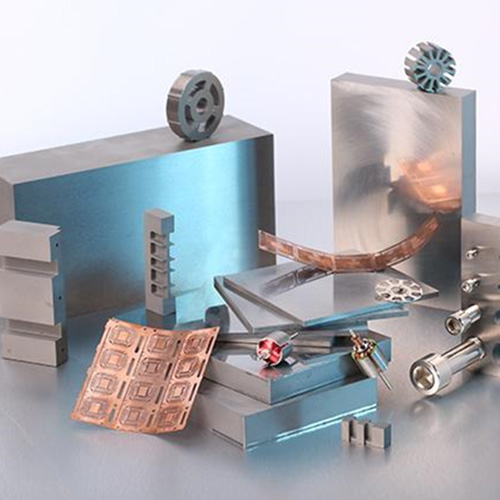

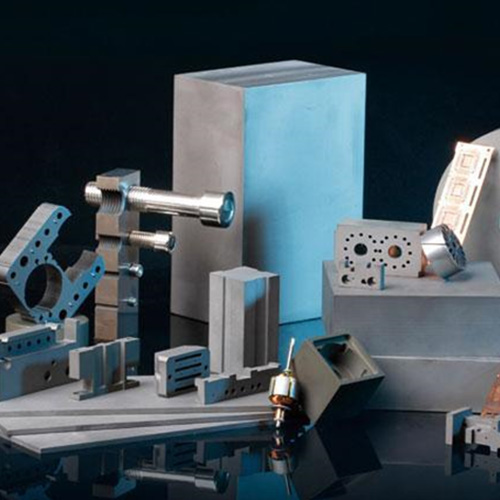

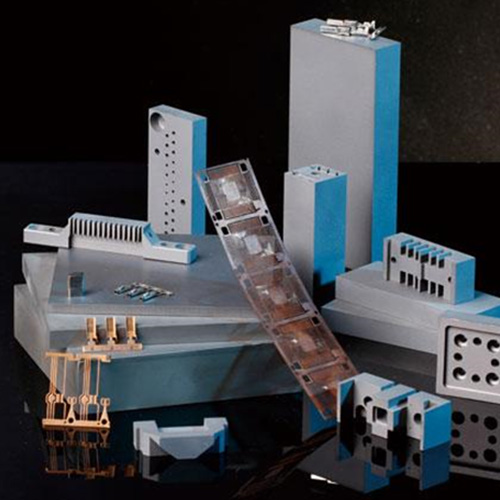

Application

Sectors, applications:

○ Automobile and Aerospace Connectors Stamping

○ Electronics and Leadframe Stamping

○ Motor Core and Silicon Steel Stamping

○ Powder Metallurgy,Pot and Plunger Production

○ All types of Metal Parts Stamping

○ High Speed Stamping Mould Production